25 biomaterial, low carbon and waste-based products to specify in 2025.

Shell Homage. Photography credits: Rania Elkalla

When we launched our first, annual biomaterials guide five-years ago, most of the projects we featured were in their embryonic stages.

From kitchen tables to university labs, innovative designers around the world were busy experimenting and pushing the limits on what had been previously thought materially impossible – perhaps presenting their ideas to a sector that wasn’t fully ready to embrace their concepts.

Fast-forward to 2025, and the bio and waste-based product offering has grown exponentially. In volume, and quality. Some of those that we featured back in 2019 have continued on, expanding their practice while gaining traction and paving the way for others to emerge and progress. Biomaterials are no longer considered ‘pie-in-the-sky’, but serious contenders in supporting the sustainable product specification that our built environment so desperately needs.

Our This Is No Longer Speculative exhibitions at Material Source Studio Manchester & Glasgow have welcomed thousands of visitors over the last 12-months – in addition to the web visits to our online campaign – all further proving just how far perceptions have shifted, resulting in a willingness to explore.

For this year’s guide, 25 biomaterial and waste-based products to specify in 2025, we have split our list into commercial interiors and built environment, with an underlying emphasis on low carbon – tying into the Net Zero Carbon Buildings Standard. You can expect more carbon-related content over the coming months – including at our Seminars – and in the meantime, here are 25 designers and projects we hope will inspire you.

Interiors

1. Rania Elkalla: Shell Homage

Repurposing discarded eggshells and various nutshells, Shell Homage is an award-winning brand offering vibrant biodegradable composite materials and products. It was founded by the multidisciplinary Egyptian designer, Rania Elkalla, during her bachelors' and masters’ research projects.

These biodegradable materials serve as a replacement for oil-based plastics and can be applied in several functional applications such as interior design, lighting and furniture design, home accessories, and 3D printing.

Despite the bio-composite being made from food waste streams (egg and nutshells), the material can resemble marble, natural stones, rubber, or glass, and the properties modified to suit different applications. The surface of the material can vary from rough to smooth, opaque, translucent, or transparent, and stiff to malleable.

Shell Homage perceives “waste” as simply being one material that can be transformed into another.

Shell Homage. Photography credits: Rania Elkalla

Shell Homage. Photography credits: Rania Elkalla

2. BlueBlocks: SeaWood Materials

SeaWood Materials are a collection of 100% natural, recyclable, and chemical-free boards made from seaweed and agricultural residuals. With wood-like strength and acoustic properties, SeaWood is ideal for interior walls, design products, and acoustic panels.

A key product in the collection is SeaVeneer, a sustainable laminate perfect for furniture and interior finishes. Crafted using ecological pigments, this range offers a wide range of beautiful, naturally-inspired colours.

The material aims to enhance interiors but also supports healthy indoor air quality for people and natural ecosystems for the planet by utilising farmed seaweed and food system waste to combine design with sustainability.

BlueBlocks / Seawoodmaterials.com - credit: Susanne Breed

3. Alma Lomholt Breun: Comfort In The Herd

Addressing the devaluation of wool through exploring the material’s potential, Alma Lomholt Breun’s graduate project, Comfort In the Herd puts forward comfort-driven interior applications for what is largely an under-appreciated material.

Alma explains, "Sheep are kept in the Netherlands for meat, milk, or grazing. The on-mass amounts of wool they produce annually, however, are not put to use. Historically, low wool prices have turned it into a burden rather than a resource for Dutch farmers. Therefore, it can often end up in landfill or is incinerated. Comfort In The Herd looks at the quality and potential of wool."

By collecting wool from farmers who would otherwise discard it, Alma analyses varieties from local breeds - Drents Heideschaap, Nederlands Bonte Schaap and Blue and White Texelaar. As she goes through the processing steps herself – sorting, washing, carding, spinning, felting, knitting and weaving – it leaves her the space to examine and extract each breed’s specific quality and suggest a specific application for each.

The collection of items was developed in order to have the finest fibres closest to the body and the rougher ones at a distance. By this, Alma seeks to show that regardless of the thickness of the fibre, locally devalued wool has tactile qualities and the potential to be reintroduced into our system.

Alma Lomholt Breun: Comfort in the Herd. Photography credits: Nicole Marnati

4. FRONT® Materials in collaboration with Alted® Materials: Paper Waste Panels

FRONT Materials’ Paper Waste Panels are crafted from discarded paper, offering a sustainable solution for interiors and design projects.

These panels are made through an innovative upcycling process that transforms waste into versatile, durable materials. Each panel boasts a unique texture and appearance, highlighting the natural character of recycled paper.

Ideal for wall cladding, furniture, and bespoke applications, they come in various finishes and colours.

By incorporating Paper Waste Panels, designers and architects can achieve environmentally-conscious spaces that combine functionality, aesthetic appeal, and a commitment to sustainability.

Images by Alted Materials - credit: Berta Julia Sala

Images by Alted Materials - credit: Berta Julia Sala

5. Interesting Times Gang: LOOM - Mycelium, Jugoso - Orange Peel Rind

During Stockholm Creative Edition 2023, Interesting Times Gang and OBOS premiered a biophilic interior design concept, featuring modular "wall-as-furniture" pieces.

The first two products, LOOM and JUGOSO, are made from mycelium and 3D-printed orange peel rinds, respectively. Developed through OBOS's 2022 design sprints, the concept focuses on circular, sustainable interior walls to combat waste and high carbon emissions in the construction industry.

The design promotes easy assembly, replaceable panels, and flexibility in material choices, extending product lifespan. The initiative aims to accelerate the use of sustainable biomaterials, with the products to be tested at OBOS's Living Lab in Oslo.

Interesting Times Gang - credit: Marcus Frendberg

Interesting Times Gang - credit: Marcus Frendberg

6. CoFlora: Cork Wallpaper

CoFlora wallpaper is fully biobased. It is made of thin slices of pressed bark of an oak tree, patched onto a FSC wallpaper backing.

The unique custom made wallpapers come in a variety of colours and natural patterns. They not only look authentic and feel good, but also make a significant positive impact on the environment. Cork is a carbon negative product, that makes spaces and projects more nature friendly.

Its practical qualities include:

- Cork wallpaper is 100% biobased

- It is dust/ water/ fire resistant

- Improves the acoustics and noise levels

- Hypoallergenic/ Hazardous chemicals free/ safe for babies

- Zero waste production/ eco positive

- Durable, scratch/stain resistant

CoFlora is available in widths of 50 and 100cm.

CoFlora - credit: Gabriela Pereira

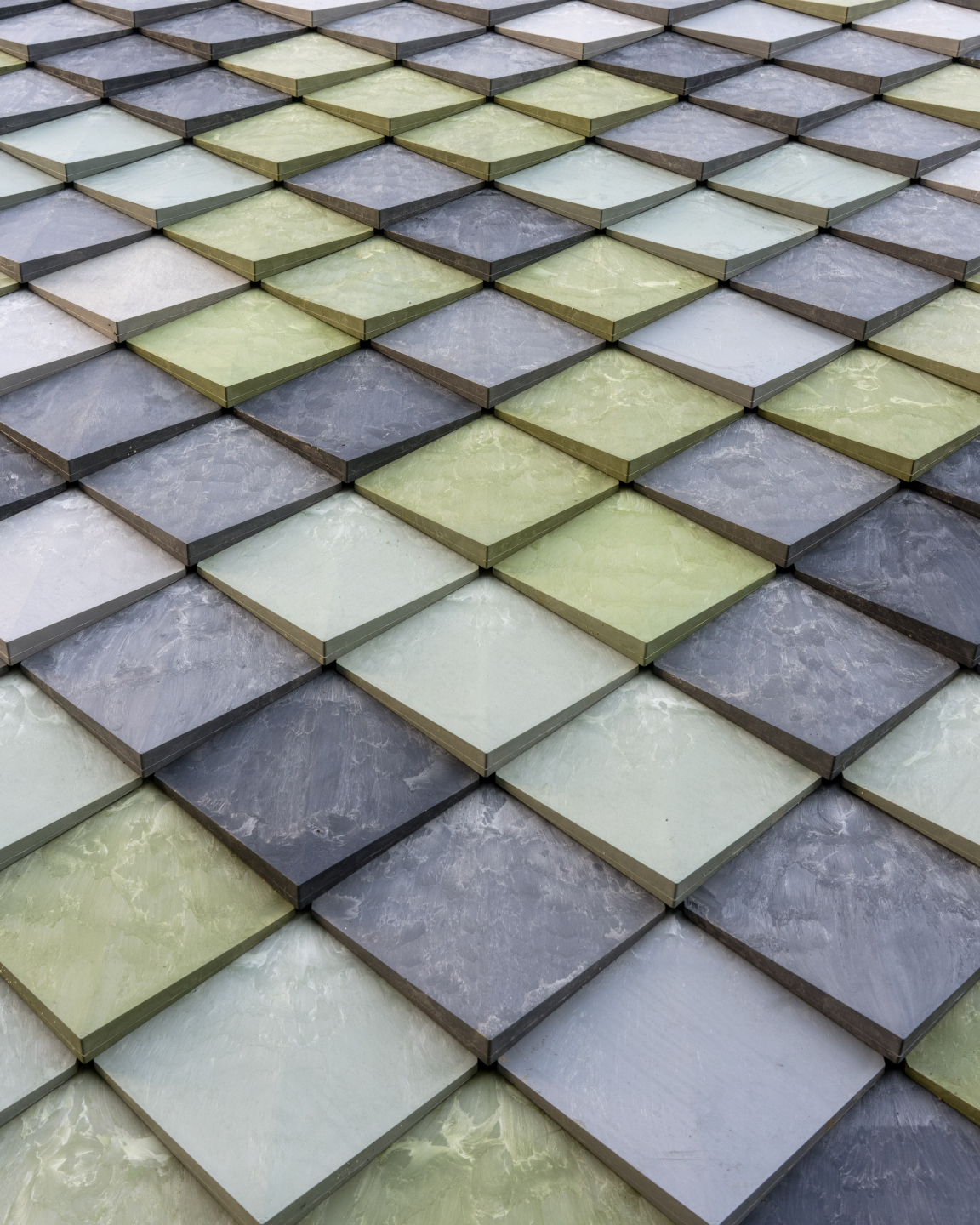

7. Studio Peipei: Recycled Glaze

The ceramics industry consumes a large amount of raw materials extracted from mines all over the world. This can be both environmentally damaging and a resource-intensive process.

Studio Peipei's Recycled Glaze instead uses locally available sawdust from natural stone, previously disposed of in tonnes. Its properties are "almost perfect" for glazes and make it possible to dispense with the usual main ingredient, quartz sand.

In addition, the otherwise long list of additives usually apparent in glazes has been limited to just two local ingredients. The same approach is followed in the packaging, which consists predominantly of other industrial waste.

With all its refined details, Studio Peipei's glaze aims to show "a better way" for industrial products through the use of waste.

Credit: Benedikt Peirotén/Studio Peipei

8. Nawa: Repit

RePit is a sustainable design project that transforms discarded date pits into reusable materials, while bridging tradition and innovation.

By harnessing the potential of agricultural waste, RePit reimagines date pits as a valuable resource for 3D printing, offering an eco-friendly alternative to conventional materials.

This project not only highlights the untapped potential of local by-products but also celebrates the rich cultural heritage of Oman’s date palm farming. The pilot project features a collection of unique, 3D-printed tiles inspired by the natural patterns of the desert dunes.

"RePit is a testament to the power of design to address environmental challenges and create a circular economy rooted in local materials and craftsmanship."

Nawatec.com

Nawatec.com

9. MycoWorks: Reishi™

Reishi™ is the first luxury biomaterial using MycoWorks' revolutionary Fine Mycelium™ technology, which engineers mycelium (the root structure of fungi/mushrooms) to form proprietary, interlocking cellular structures producing the highest-calibre natural materials in performance and aesthetic standards. Reishi™ is said to be "worlds ahead in hand-feel, draping, strength, and durability".

"Partnerships between MycoWorks’ top materials scientists and heritage craftspeople at luxury maisons and leather tanneries have allowed Reishi™ to attain quality advancements previously impossible in leather alternatives.

"Chemical-free, biodegradable, with virtually no plastic in its production, and currently the rarest natural material on the market, Reishi™ is in a league of its own".

MycoWorks

MycoWorks

10. Noa Paul: Sappa Panels

Noa Paul's hemp acoustic panels for sound absorption are cement-free and made from rapidly renewable raw materials.

Hempwood grows about 50 times faster than forest wood, and thus stores large amounts of CO2. The acoustic panels are also very easy to recycle and promote optimum indoor air quality.

They are of high aesthetic quality and can be individually adapted to suit a project's needs. Almost any colour is possible, and with Sappa, Noa can incorporate individual millings and supply the panels in different shapes.

"The combination of consistent ecology with the highest aesthetics and the best sound absorption values makes it a unique product".

Noa Paul, Sappa Panels - credit: Schönthaler Werner

11. Studio Sanne Visser: Human hair yarn, Human hair rope

Studio Sanne Visser is a material design research studio focused on exploring material innovation and future thinking through making and learning for circular worlds. The studio specialises in regenerative design, systems thinking, and sustainable solutions, with a unique emphasis on using human hair as a resource.

Through exhibitions, workshops, and collaborations with leading institutions globally, Studio Sanne Visser is at the forefront of driving material change and circular design.

Sanne Visser, the founder and director, is a material explorer, designer and researcher with over nine years of experience working with hair. She graduated from Material Futures at Central Saint Martins in 2016 and has since exhibited her work at major institutions worldwide, including the Textielmuseum, Museu del Disseny de Barcelona, Science Gallery Dublin, and the Design Museum.

Her main interest as a design researcher is material innovation, regenerative design and systems thinking. Alongside running her practice, Sanne is an Associate Lecturer and PhD researcher at the University of the Arts London. Her work has gained global recognition and media attention, with nominations for prestigious awards, including the AFFA and New Material Award.

Sanne's latest project involves the transformation of human hair into practical products for interior use.

Studio Sanne Visser

Studio Sanne Visser

12. Agne Kucerenkaite: Ignorance is Bliss

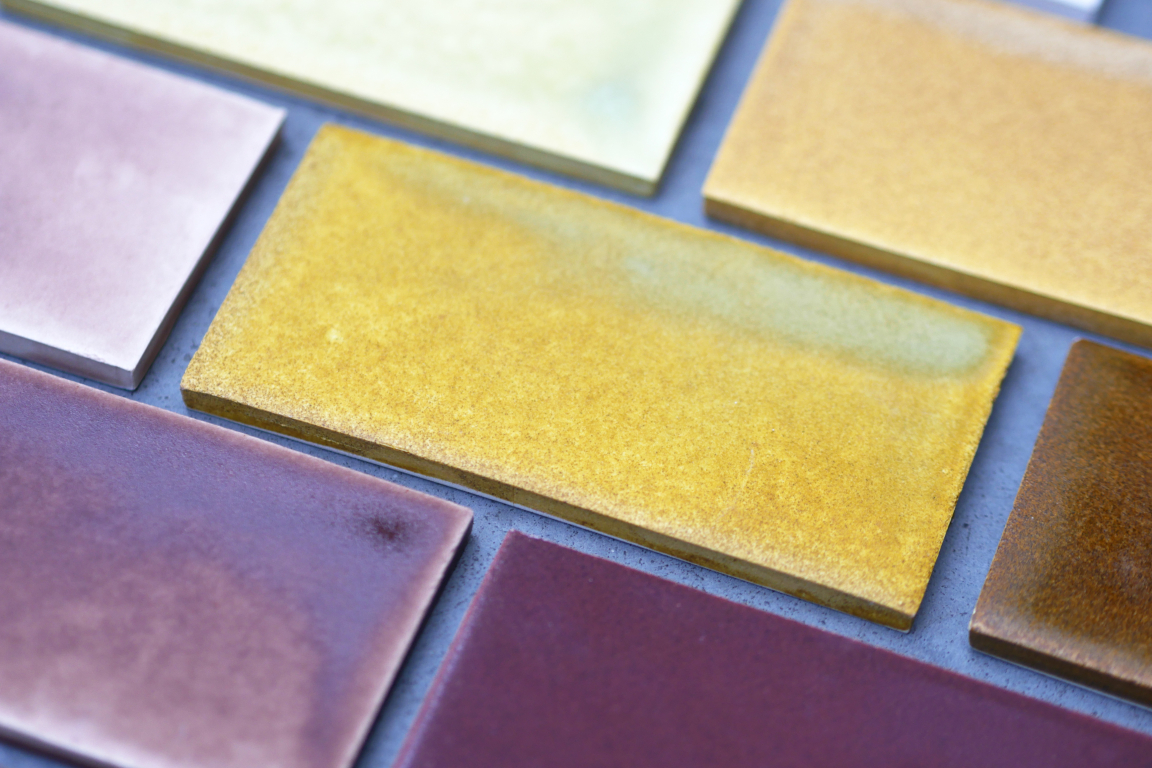

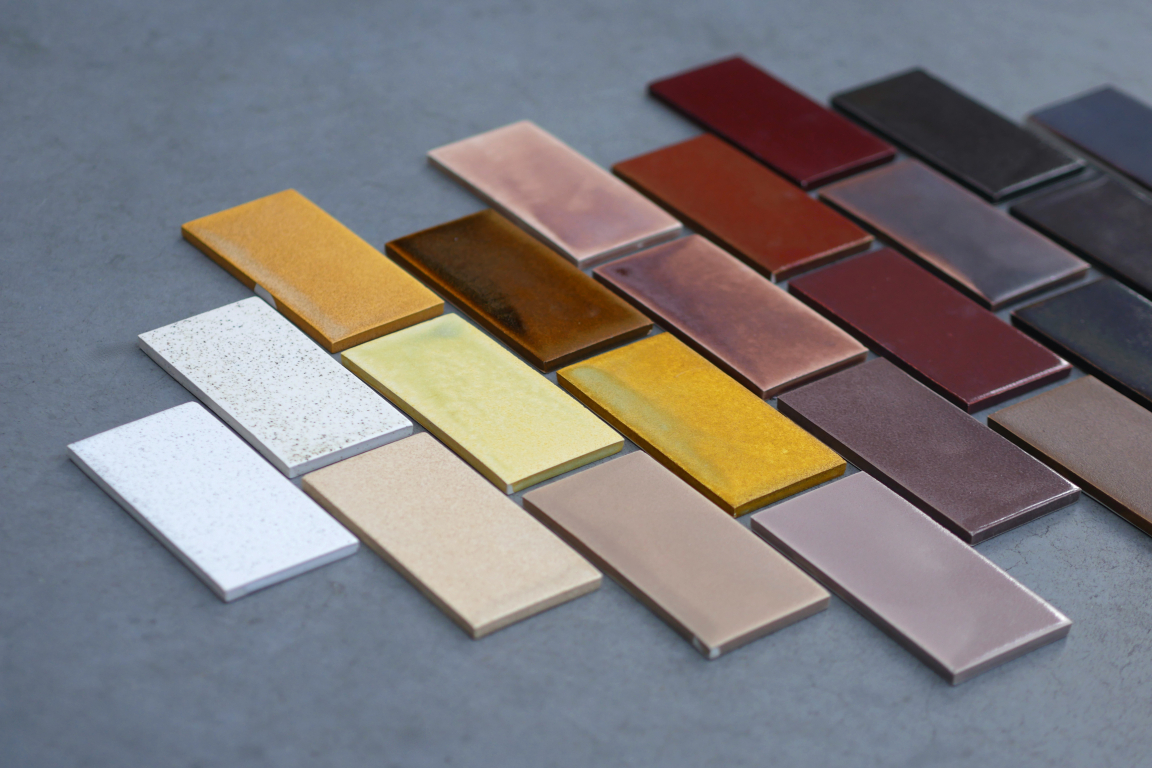

Ignorance Is Bliss ceramic tiles are glazed using pigments derived from industrial metal waste and by-products, avoiding the need for mining and excessive processing.

With up to 50% waste content, the glazes source materials from industries like drinking water supply and soil remediation, which generate thousands of tonnes of residue annually.

The collection features over 20 carefully curated colours, the result of years of extensive research. Tiles are handmade, leading to subtle variations in shades.

Free of led and barium, the tiles are designed with environmental responsibility in mind, and are evolving towards full circularity with innovative materials such as biofuel waste.

Agne Kucerenkaite/Ignorance is Bliss

Agne Kucerenkaite/Ignorance is Bliss

13. Koukos de Lab: Koukoutsi Eco-Material

Koukoutsi is a sustainable materials brand that transforms the byproducts of olive oil production into versatile, eco-friendly materials, championing circular economy principles.

Sourced exclusively from olive oil factories on the island of Lesvos, home to over 11 million olive trees and the largest olive grove in the world, Koukoutsi leverages this abundant resource to embody zero-waste principles, delivering both sustainability and high performance.

Founded with the goal of reducing agricultural waste, Koukoutsi began by creating decorative and functional surfaces, evolving to cater to the growing demand for innovative, waste-based materials in architecture and design.

“Our aim is to reimagine waste as a resource, creating materials that are not only sustainable but also enhance the aesthetic and functional potential of design projects.”

Koukos de Lab | George Komvokis @koukosdelab @george_komvokis

14. Mariekke Jansen: Discarded wool - via Mia Karlova Galerie

Mariekke Jansen repurposes discarded wool to create her distinctive lounge chairs. Her process is as innovative as it is practical – Mariekke folds wool into itself to form a structure that is both supportive and comfortable, thus elevating a material usually seen as mundane into one of luxury and strength.

By embracing traditional techniques such as tufting and felting, Jansen’s work not only preserves the material but also highlights its inherent qualities – resilience, softness, and sustainability. Her lounge chairs showcase the beauty of reinvention while suggesting that design can be both functional and environmentally conscious.

Credit: Mia Karlova Galerie

Built environment

15. Pretty Plastic

Pretty Plastic is a Dutch company that creates sustainable, 100% recycled PVC wall and roof cladding materials. From trash to tile, these commercially ready materials are made from old window frames, downspouts and rain pipes. With three different product types; Pretty Plastic First One, Pretty Plastic Second High, and Pretty Plastic Basic Third, the Pretty Plastic product portfolio offers both sustainable and durable materials, with a unique look.

These tiles are weatherproof and designed to meet building standards, allowing architects and builders to incorporate circular materials into their projects, without compromising on aesthetics or quality.

By transforming waste into functional building materials, Pretty Plastic supports the circular economy and promotes sustainable construction practices.

Pretty Plastic. Photography credits: Maarten van Apeldoorn

Pretty Plastic. Photography credits: Maarten van Apeldoorn

16. Serame Studio: Minimal Matter

Driven by the brilliance of natural efficiency, project Minimal Matter by Serame Studio translates the complex geometries of minimal surfaces into architectural forms that respond to environmental and functional demands.

Rameshwari Jonnalagedda is a graduate from the Bartlett School of Architecture. Developed during her Master’s at UCL and advanced through her practice, Serame Studio, Rameshwari aims to explore the potential of minimal surfaces—defined by their high surface area-to-volume ratio and cellular porosity—in creating structures that balance material and structural efficiency.

Utilising 3D-printed red terracotta clay, the foundational idea is to create adaptable frameworks for diverse applications, from eco-conscious facades to biodiversity-supportive systems, adjusting geometry and cell type for each need.

This method applies nature-driven strategies, envisioning a future that is responsive to its context.

Minimal Matter by Serame Studio

Minimal Matter by Serame Studio

17. Strawcture Eco: AgriBioPanel™

Strawcture Eco is on a mission to research, manufacture and promote plant-based building materials that decarbonise the built environment. AgriBioPanel™️ is its first proprietary product, made of 95% agricultural residue. Each sqm of an 11mm AgriBioPanel™️ stores 3.2 kg of CO2.

The engineered panel is insulating, has the lowest ecological footprint, and offers a versatile surface for any kind of aesthetics on it. AgriBioPanel™️ can be used for making load bearing drywall partitions, cladding, false ceilings, furniture, and bespoke acoustic solutions.

The panels are certified to Indian and European Standards, and are currently being used in India, Italy, Singapore and the UK.

AgriBioPanel™ by Strawcture Eco

AgriBioPanel™ by Strawcture Eco

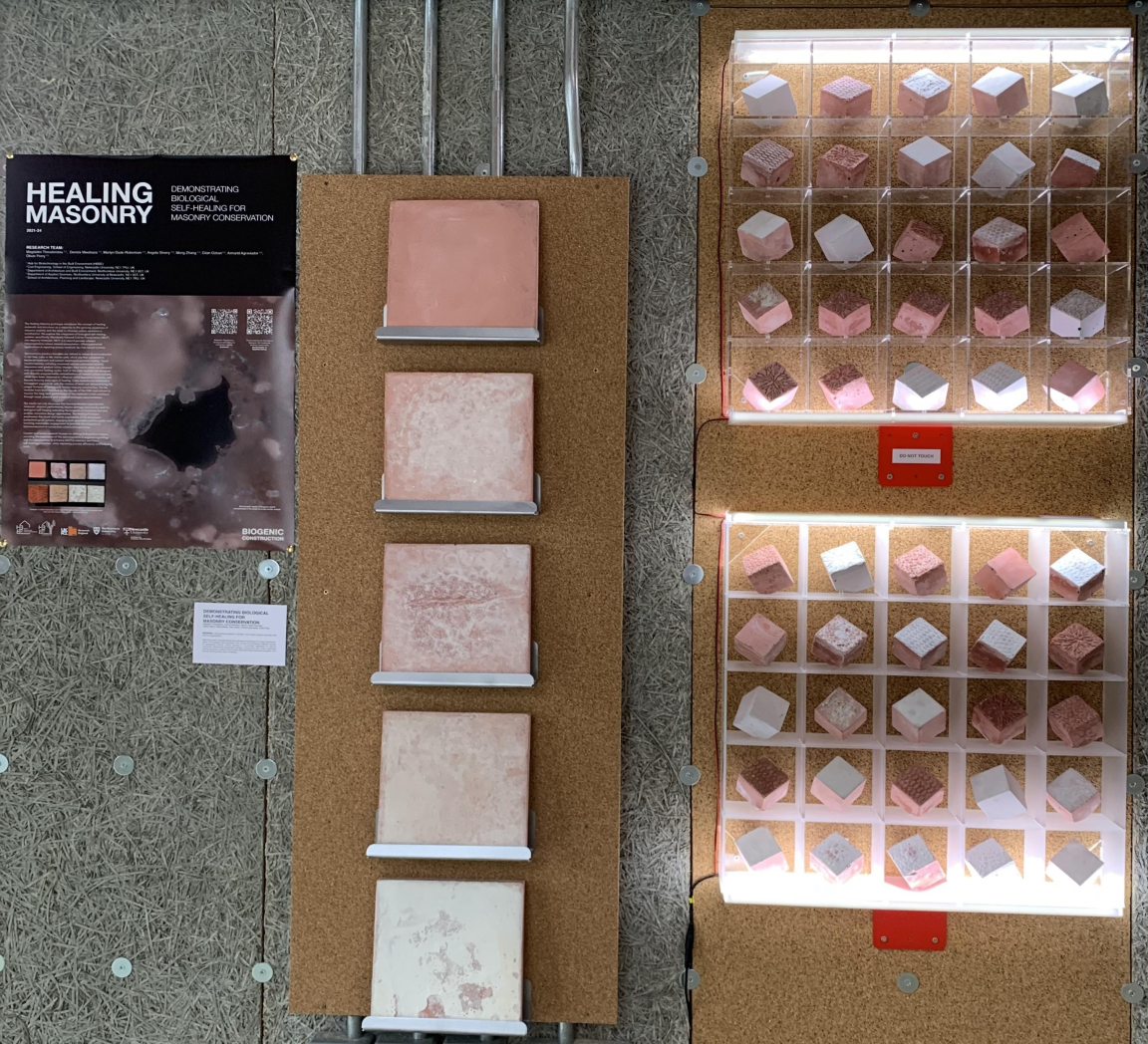

18. Hub for Biotechnology in the Built Environment: Healing Masonry

Cement manufacturing accounts for roughly 8% of the world CO2 emissions, consuming about 3% of its energy supply. Battling this environmental challenge with bacteria is The Hub for Biotechnology in the Built Environment (HBBE).

HBBE combines two research clusters; Architectural Design and Engineering at Newcastle University and Biotechnology at Northumbria University to develop biotechnologies that create a new generation of ‘Living Buildings’.

Its vision is to develop buildings that are responsive to their natural environment; grown using living engineered materials to reduce inefficient industrial construction processes. These buildings, HBBE believe, can metabolise their own waste, reduce pollution, generate energy and high-value products, and modulate their microbiome to benefit human health and wellbeing.

“Biotechnology bridged with heritage-inspired building technologies can offer alternative solutions in construction”, says Dr. Magdalini Theodoridou, NUAcT Fellow at Newcastle University’s School of Engineering and Lead of the HBBE’s project Healing Masonry. “In particular, focusing on the adaptation and reuse of the existing building stock through the development of disruptive smart technologies, such as biological self-healing system, further highlights the potential of that collaboration to offer sustainable material solutions and new approaches in the field.”

Their interdisciplinary research into self-healing masonry leverages biotechnology to repair and prevent damage in masonry structures. This innovative approach utilises bacteria to precipitate calcium carbonate in composite materials sealing cracks and enhancing durability. The developed self-healing system offers sustainable solutions for both contemporary and existing architecture, including heritage structures.

Reducing maintenance costs, energy consumption and the additional use of raw materials, this solution preserves structural integrity and extends the lifespan of structures while minimising environmental impact.

"Our commitment to supporting the decarbonisation of the built environment stems from the necessity to develop smart technologies to promote adaptation and reuse of existing structures as an alternative to new construction", says Dr. Theodoridou.

HBBE: Healing Masonry

HBBE: Healing Masonry

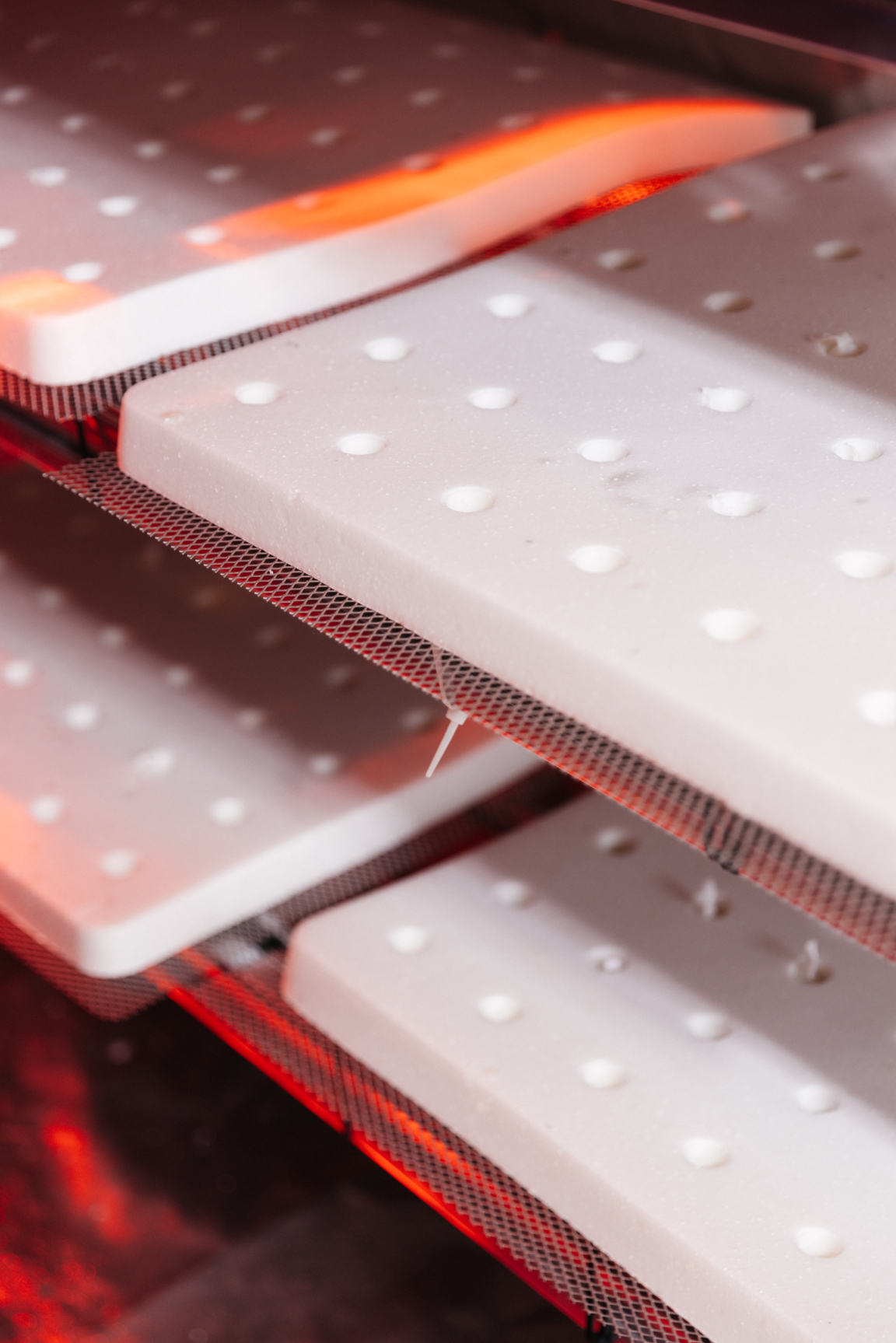

19. Agoprene: Agoprene Foam

Agoprene is a super durable bio foam made from renewable seaweed biomass and other bio-based ingredients.

It's designed to mimic the durability and comfort of polyurethane, without the environmental downsides. It’s 100% petroleum-free, addressing the need to reduce CO₂ emissions, reduce reliance on petrochemicals, and offer a product that can either be recycled or biodegrade naturally in soil.

Unlike conventional foams, Agoprene is denser and more durable, with a feel that's closer to latex. Its semi-closed-cell structure provides comfort and longevity, making it ideal for upholstery applications. Built to last, it has passed testing for a 10-year lifespan and meets the strict Crib 5 fire safety standard.

By working closely with the furniture industry, Agoprene combines sustainability with practicality, offering a dependable alternative to traditional foams while keeping the environment in focus.

Agoprene Foam

Agoprene Foam

20. Studio Akēka: Trilix Bamboo Pavilion

In collaboration with the Dutch Bamboo Foundation and Vinc Math Bamboo Consulting, Studio Akēka's Trilix Bamboo Pavilion, commissioned for the New European Bauhaus Festival, reappeared at Dutch Design Week 2024.

The innovative structure, built with locally harvested and EU sourced bamboo poles, features an intricate skin using hand-split bamboo. Bamboo species used include Phyllostachys Moso and Phyllostachis Vivax for the skin and façade. Handmade bamboo splits and seating were crafted out of MOSO Bamboo X-treme® - engineered bamboo.

The pavilion demonstrates bamboo’s promise as a sustainable and rapidly renewable building material.

Credit: Max Kneefel

Dutch Bamboo Foundation

21. Graphene@Manchester: Graphene Enhanced Concrete

The Graphene Engineering Innovation Centre (GEIC) at the University of Manchester is advancing sustainability in the construction industry by integrating graphene into cement and concrete.

These innovations reduce the carbon footprint of construction by decreasing the need for materials like concrete and steel. From lab experiments to large-scale site trials, GEIC has found graphene admixtures to deliver improvements in compressive, tensile and flexural strength in concrete, accelerated curing time, crack reduction and reduced water and salt permeation.

The GEIC’s state-of-the-art testing facilities support industry collaboration, enabling certification and broader adoption. By driving advancements in smart, low-carbon materials, the GEIC contributes to the evolution of sustainable construction and the global journey toward hitting net-zero targets.

Graphene – The University of Manchester

22. Lotte Wigman/Studio Lotek: SEACRETE

Seacrete is an innovative, biodegradable material formed from lime derived from oyster and mussel shells, combined with a seaweed binder. These elements, sourced from Dutch aquaculture, remain within their natural ecological cycle as the material erodes.

Designed for structures that adapt to environmental changes, Seacrete embraces sea-level rise, evolving from human-use spaces into marine biotopes. By supporting biodiversity and enriching ecosystems as it dissolves, Seacrete fosters a positive feedback loop for marine life.

This low-impact alternative to traditional materials embodies a regenerative design philosophy, restoring ecosystems and rethinking construction as a process in harmony with natural cycles.

Credit: Studio Lotek

Credit: Studio Lotek

23. Vector Homes/Wool Insulation Wales: Lamda

Wool is an incredible and abundant resource, yet globally under-utilised, with approximately 32 million kg produced annually in the UK as a by-product of sheep farming. Despite its significant potential, wool remains undervalued, with farmers receiving only 15-30p per fleece while paying over £1 for shearing, resulting in net losses. The situation is even worse in Europe, with around 70% of the annual production of wool being discarded by farmers to landfill.

Wull Technologies sees this as an opportunity to transform wool into a highly technical building material. Wool is naturally flame-resistant, and provides excellent thermal and acoustic insulation properties. Its natural crimp gives it elasticity and helps trap air, making it an ideal material for both energy efficiency and safety in construction.

Additionally, wool is biodegradable, antibacterial, improves indoor air quality through being breathable and capturing harmful gases and odours, and capable of absorbing moisture without feeling wet.

Lamda is Wull Technologies' flagship product—a rigid wool panel technology designed as an environmentally friendly alternative to traditional insulation materials. Made from 100% British sheep wool (i.e. it is totally plastic free), Lamda provides excellent thermal and acoustic insulation, while being completely circular. This technology leverages and builds on wool's natural properties, such as its flame resistance, breathability, and biodegradability, making it a high-performance, sustainable option for modern construction.

"Our rigid wool panels are designed to displace oil-based insulation products, providing a superior and efficient solution that also supports local farmers by creating value for wool that would otherwise be wasted.

"The Lamda panels are versatile, suitable for a range of applications including external wall insulation, floor insulation, and acoustic panels in home and office environments, ensuring that they can meet the diverse needs of the construction industry."

Lamda

24. The Hemp Block Company Ltd: Hemp Blocks

The Hemp Block Company's insulation blocks have been designed to promote a healthier living environment through reducing the impact of the construction industry.

With multiple benefits, from supporting healthier homes and the planet through using bio-based materials, to reducing running costs, requiring no special tools or machinery, and being light, easy to handle, and, due to their size, progress with them on site happens fast, Hemp Blocks are a solid insulation option all-round.

William Stanwix, Stanwix Ltd

25. Clayworks: Rammed Earth

Clayworks’ Rammed Earth finishes have been developed as an answer to the complex and technical challenges of building with monolithic mass - an ancient, natural construction method. Traditional rammed earth architecture requires many tonnes of compressed earth to create buildings with structural integrity, prohibiting its use and viability in most urban and retrofit contexts.

This collection is made from 100% natural clays, minerals, and sands, and is coloured with natural earth pigments, emulating the textural and tonal characteristics of monolithic earth architecture. Each layer is produced, pressed and compacted by hand, and so the colour and width of layers is entirely customisable through Clayworks’ bespoke finish service.

Using no water and producing minimal waste in the production phase, the Rammed Earth finish is a low carbon design alternative omitting harmful chemicals or VOCs (volatile organic compounds). The environmental impact of using Clayworks means saving up to 2.4 kilograms of embodied carbon per square metre of construction.

Clayworks - Credit: Elliot Sheppard

And there we have it, our round-up of the top 25 biomaterial, low carbon, and waste-based products to specify in 2025. We’ll be continuing the conversation at our upcoming Seminars in Manchester & Glasgow. Find out more, and book your tickets here.

Plus, we’ll be expanding our materials libraries in both Studios, so you can experience these materials up-close in the New Year. In the meantime, do you have any to add? Let us know!