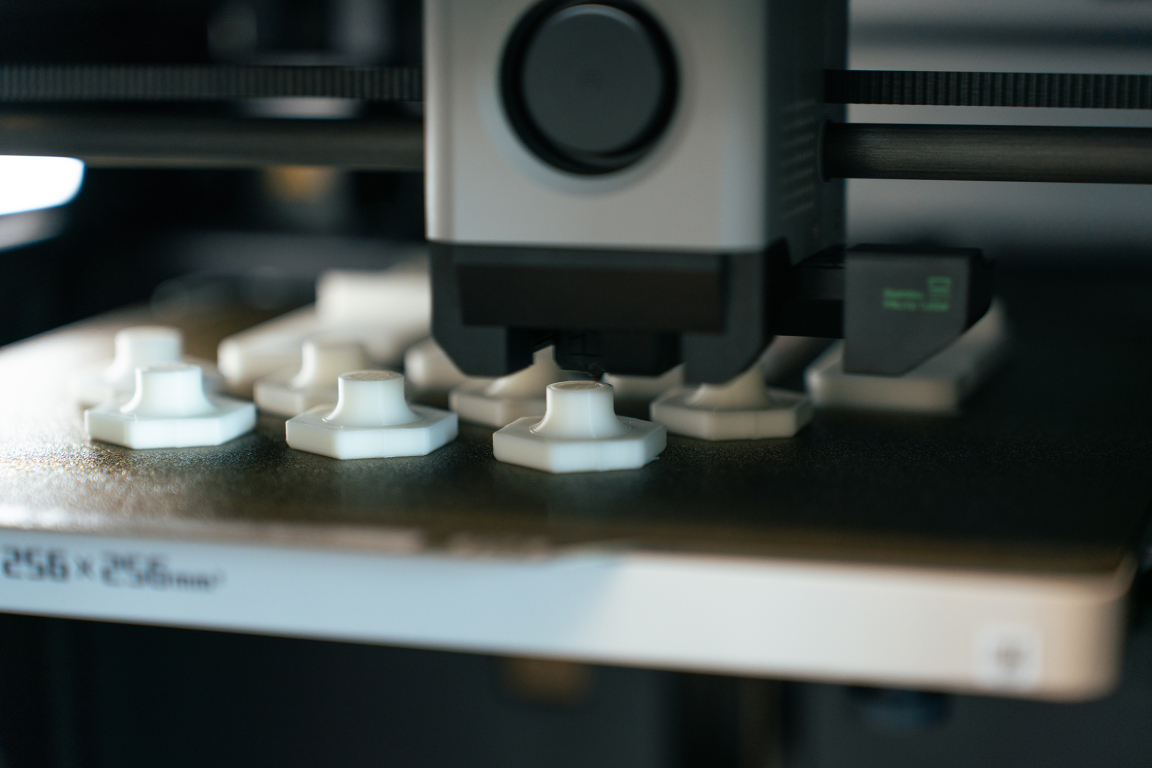

Autex Acoustics’ SpinFix adopts circularity principles to bolster product recyclability.

Autex Acoustics’ SpinFix has been developed with the entire product lifecycle in mind - offering end-of-life solutions to reduce environmental impact.

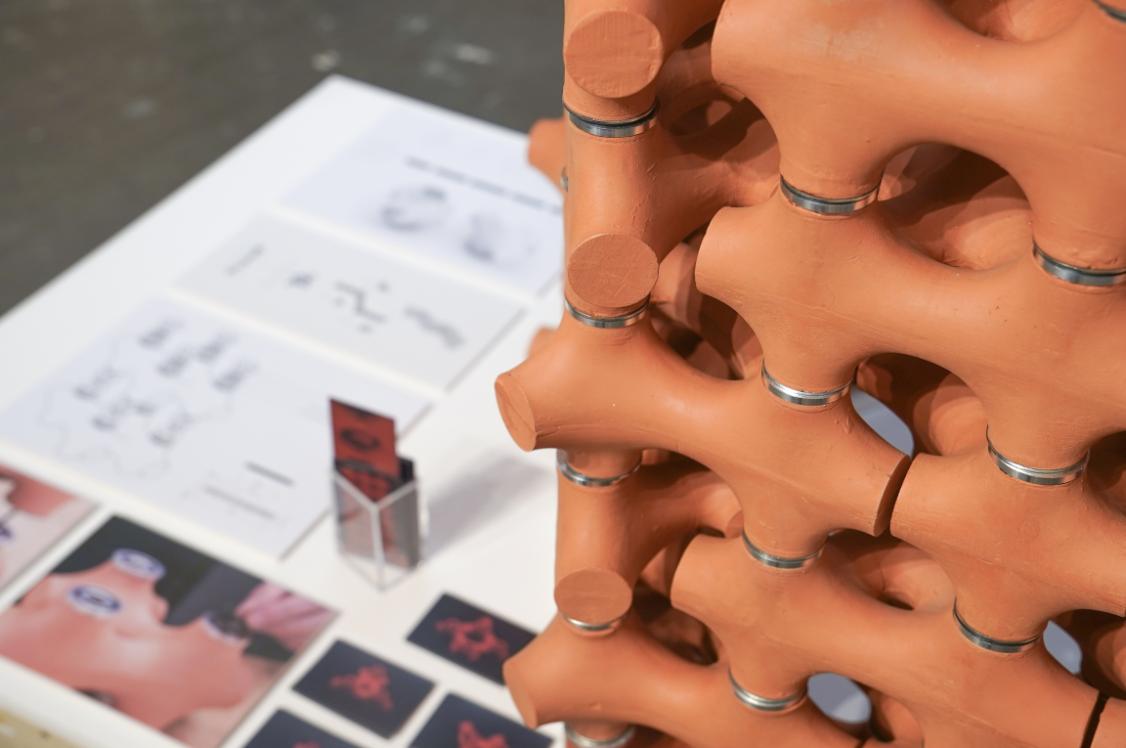

The sustainability benefits with SpinFix mounting clips are two-fold. Firstly, by harnessing its cutting-edge pelletising process, Autex crafts the fixtures from RePET - converted ‘waste’ PET from manufacturing leftovers. And secondly, by using SpinFix the need for adhesives during installation is eradicated, making products recyclable.

Sam Wells, product development lead at Autex, comments, “Improving the end-of-life journey for our materials was top of mind when designing SpinFix, providing us with another avenue to explore applications of our RePET processes and giving acoustic panels yet another life.

"Our friction welding technology binds the 100% PET clips to the panels without the use of glue. This means everything remains 100% polyester and can be recycled again at the end of life. Without compromising the performance or usability of the original product, we’ve ended up with an extremely versatile technology, which we will explore and develop even further in future.”

Autex takes a holistic approach to product lifecycles, including the end-of-life phase, by focusing on materials with lower environmental impact, as well as seeking sustainable design and manufacturing methods.

SpinFix is specifically engineered for easy disassembly, facilitating the repurposing of panels or their reclamation and recycling through the Takeback Programme, thanks to the elimination of any contamination associated with installation.

To find out more about how Autex can craft solutions to suit your consciously-designed scheme, click here, and visit Material Source Studio Manchester & Glasgow where it is a Partner.