CMF designer, Chris Lefteri on re-defining luxury via the ‘Wild West’ of materials and sustainability.

Photography credits: Fangzou Yin

Chris Lefteri of Chris Lefteri Design is an authority on the application of CMF.

CMF, the all encompassing term coined for ‘Colour, Material and Finish’, is an evolving yet still underrated design discipline according to Chris, though it proves crucial in determining the material makeup of the products and services we use every day.

Back in 2001, Chris published the first of eight books on materials, promptly following the establishment of his own CMF design studio - comprising a team of internationally spread and materially curious experts operating in China, South Korea and the UK.

The design studio works with a host of globally recognised brands - from Chanel to British Airways and Google, to name a few - on effective material integration into the design process.

Chris also lectured at Central Saint Martins on the topic of CMF for more than 18 years.

When asked about the impact of sustainability on his work, the question as to what constitutes a 'sustainable material' is no longer relevant to ask, says Chris in our discussion that follows. It’s vague, and uninformed. Under the vast umbrella of sustainability, a material can perform in a multitude of different ways, whether it be energy efficient, have low embodied carbon, or reduce waste streams. Asking specific questions, Chris explains, is how we bridge the gap between materials and sustainability.

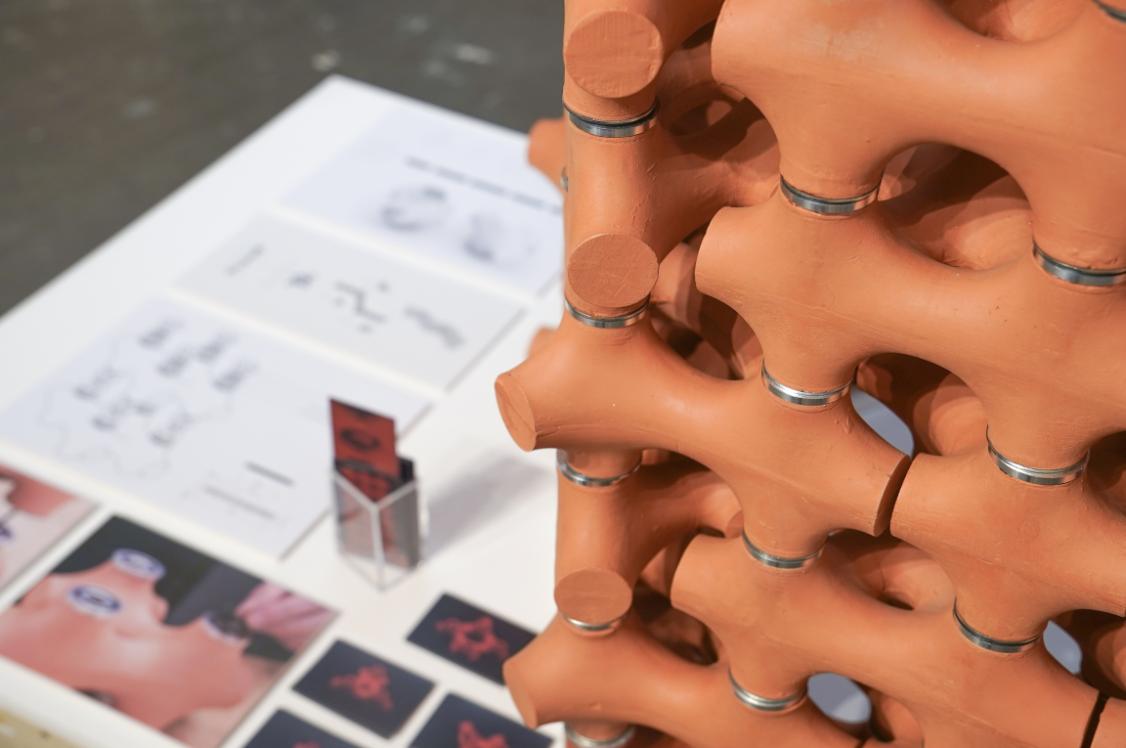

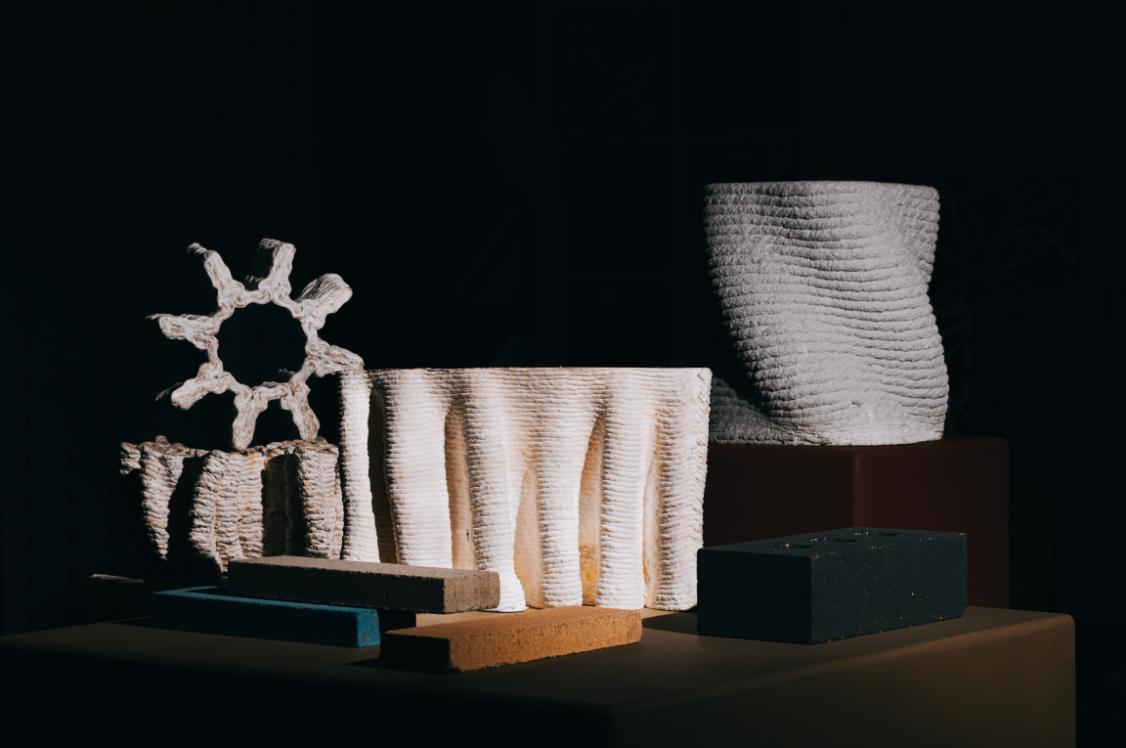

Following the studio’s ‘Materials Lab’ installation at Design Mumbai, here follows our sit down chat about the power of CMF, changes in the industry to-date, and how sustainability should be considered within materials and manufacture…

Firstly, can you please introduce us to Chris Lefteri Design?

“The studio is probably one of the only studios in the world that combines industrial design, materials and trends.

“Initially, after writing my books, I worked on materials research for corporations. Now, Chris Lefteri Design encompasses a wide range of activities; from research into trends, to developing production pieces.”

How did you get started?

“I was first interested in materials when I graduated from the Royal College of Art, after studying industrial design.

“Very simply, I had an idea to write a book about materials because at the time, it wasn’t something that I had seen before, and I was fortunate enough to be introduced to a publisher.

“After publishing the first book on plastics, the editor commissioned another five. Which is near when I started writing about manufacturing processes, and an update to those original materials books.

“I suppose the interest in materials was born out of my own curiosity to find out how things are made and what things are made from. I wanted to share those stories with other designers. I also love collecting, so my office is filled with thousands of samples.”

And what does your team look like today?

“We’re a really small team of eight people and very international. The main office is based in London, but there is also an office in South Korea and China. It’s very multinational with Italian, Danish, Korean, and Chinese designers.”

Photography credits: Gianni Diliberto

What are your key considerations when selecting materials for a design project?

“At the end of the day, material selection for us is about building value to ensure they communicate to the end user, the consumer.

“We have to make sure that the message has got through to the designers in the company that we work for, and make sure our vision is carried forward to the end product.

“Of course colour plays a huge part in making sure that the emotional value is there for the consumer. We break down materials into the functional, sensory, and emotional value they can bring. The emotional value being the most important.”

“CMF is the first thing that you encounter when you see a brand. It’s the first impression, with the ability to totally change your perception of the product.”

Who generally are your clients?

“We are really fortunate to work with large brand owners that range from automotive, consumer electronics, appliances, FMCG - some of the biggest companies in the world.

“We also work with material suppliers by helping them communicate the value of their materials through samples and messaging. This is so it communicates effectively to designers, helping them make informed decisions.”

And how do you approach collaborating with them? Is a brief different every time or are there common threads throughout?

“That’s a a great question because actually we have to help clients put together a brief. It’s not unusual the client has never worked with a company like us before. So we have to advise on what we think the best approach is, to ensure that we can have the biggest impact for the project within the organisation and beyond. Essentially, it’s a lot of handholding.”

Can you share with us how trend forecasting influences your approach in selecting materials?

“Trend forecasting has a huge role to play in our work. It gives context to the project and helps fine tune the message.

“Any given material can be processed, coloured, shaped into a thousand different stories and tends to have very important influence on the texture, the colour patterns applied to the materials.”

How has the CMF industry changed during your career?

“Yes, that’s a fantastic question. When I started in 2001, I don’t think there really was anything called the ‘CMF industry’. It was limited to car interiors and applying patterns and textures. Now, it has evolved into a massively important industry. However, I still believe it’s an underrated discipline within design.

“CMF is the first thing that you encounter when you see a brand. It’s the first impression and it has the ability to totally change your perception of the product.

“I’m a huge fan of Apple products and the original iMac was one of the most thrilling and important, innovations in CMF. The idea that - through the application of colour translucency and form - you could completely change the nature of computers from something that sat under your desk, to something that you were proud to display in your home. It changed computing from function to fun.”

“For every good thing about a material, there is a consequence.”

What are some of the most common misconceptions surrounding sustainability with regards to materials and manufacture?

“It is such a complex issue! Somebody referred to sustainability and materials as the 'Wild West'. What they were referring to was the notion that it is a complicated and constantly emerging field, that is difficult to grapple with.

“I wouldn’t say there are big misconceptions. I would say that you have to be precise with the question that you want to ask. The language of sustainability has involved considerably. Before, you could ask: What’s a sustainable material? That’s no longer a relevant question because it’s so vague and general.

“Instead, you need to ask: Do you want to reduce waste, do you want to reduce CO2, or do you want to reduce energy? For every good thing about a material, there is a consequence. It is just a balancing game.”

Photography credits: Gianni Diliberto

Photography credits: Gianni Diliberto

You work in a wide range of different sectors, from apparel and automotive, to technology. Which industries have the most work to do in regards to sustainability, in your opinion? And which are leading in this field?

“The electronics industry faces the biggest challenge. I say this partly because of the packaging materials, and to some degree the fashion sector has a much more advanced recycling industry behind them.

“However, you just have to look at the turnover of products like mobile phones, or increasingly monstrous big flatscreen TV screens. These items get updated so regularly, causing piles upon piles of electronics in local refuse collection facilities and landfill. It’s depressing to see.

“A leading company that springs to mind in relation to sustainability is Logitech, they have a very defined strategy in place. Polestar also has some very inspiring studies on sustainability in their cars.”

Can you please tell us more about your installation at Design Mumbai?

“Well, I’m very grateful to Ian Rudge for inviting me again to curate this display for the inaugural Design Mumbai.

“Our curated ‘Materials Lab’ for Design Mumbai highlights the latest advancements in sustainable and cutting-edge materials, offering a glimpse into the future of design and material science.

“We wanted the audience to be fascinated by what they see, sparking imaginative applications of the materials on display.”

Photography credits: Fangzou Yin

Which materials would you like to see used more often within design?

“It’s an incredibly exciting time for design and also materials. I really can’t keep up with the amount of new materials that are being developed.

“What is particularly exciting is that, in the past, materials were being developed by chemists in labs, whereas now these new materials are being developed by designers, and largely using bio or waste-based residues. So, I really hope that these materials can reach commercialisation.

“In terms of materials I’d like see more of, it’s more that I’d like to see a change in the way that we perceive qualities such as luxury. Quite often it’s associated with bright shiny metals and chrome finishes. These choices are obviously not the best materials from an environmental perspective, but we still place them high in terms of desire, so I'd like to see more alternatives to these.”

And finally, what projects have you got in the pipeline?

“In 2025 there will be more collaborations with our Chinese client, TCL. These will be focused on its appliances, and introducing more nature-inspired, sustainable materials to its product portfolio.

“Towards the end of the year, we will be launching our own CMF collection in collaboration with our partner, Model Solutions. This will be our chance to show our ideas for future materials and aesthetics through samples that we will design, develop and make in a purely experimental way.”

To learn more about Chris Lefteri’s CMF design practice, click here.