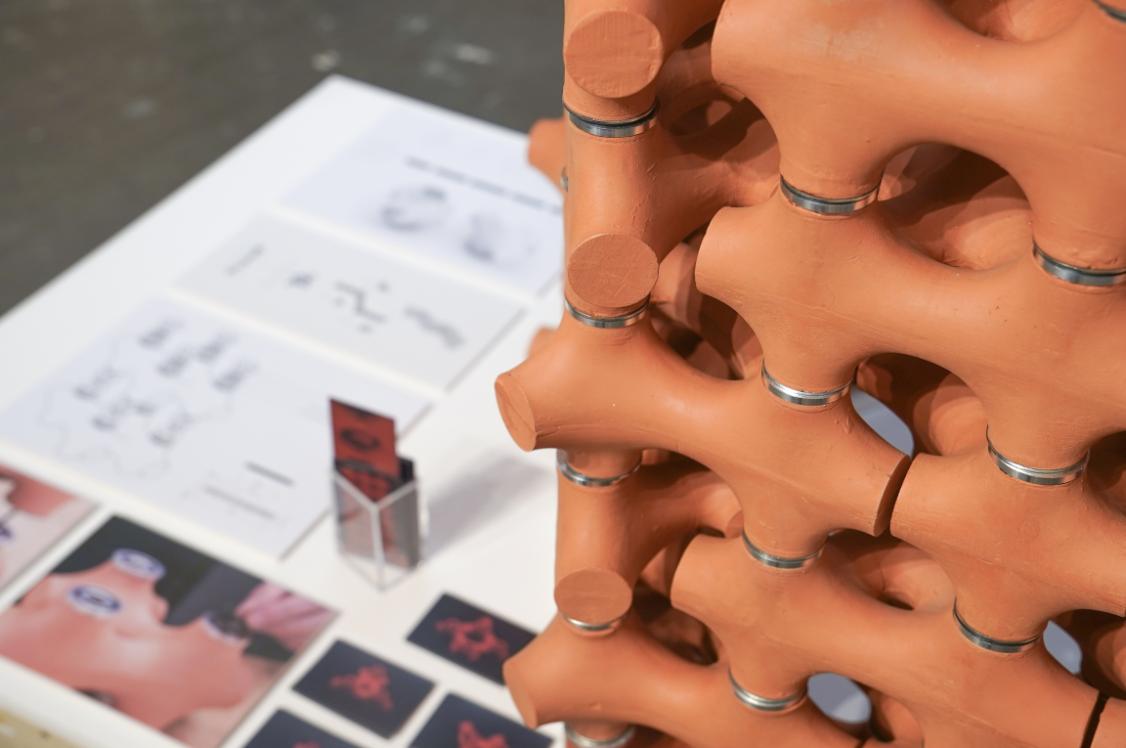

How will materiality help us hit Net Zero?

Credit: Tim Ainsworth

With the 1.5 °C global warming threshold at breaking point, the need to achieve Net Zero has never been more urgent.

It’s reported that roughly 40% of carbon emissions come from the construction, operation, or maintenance of buildings - putting built environment professionals in a powerful position to instigate change.

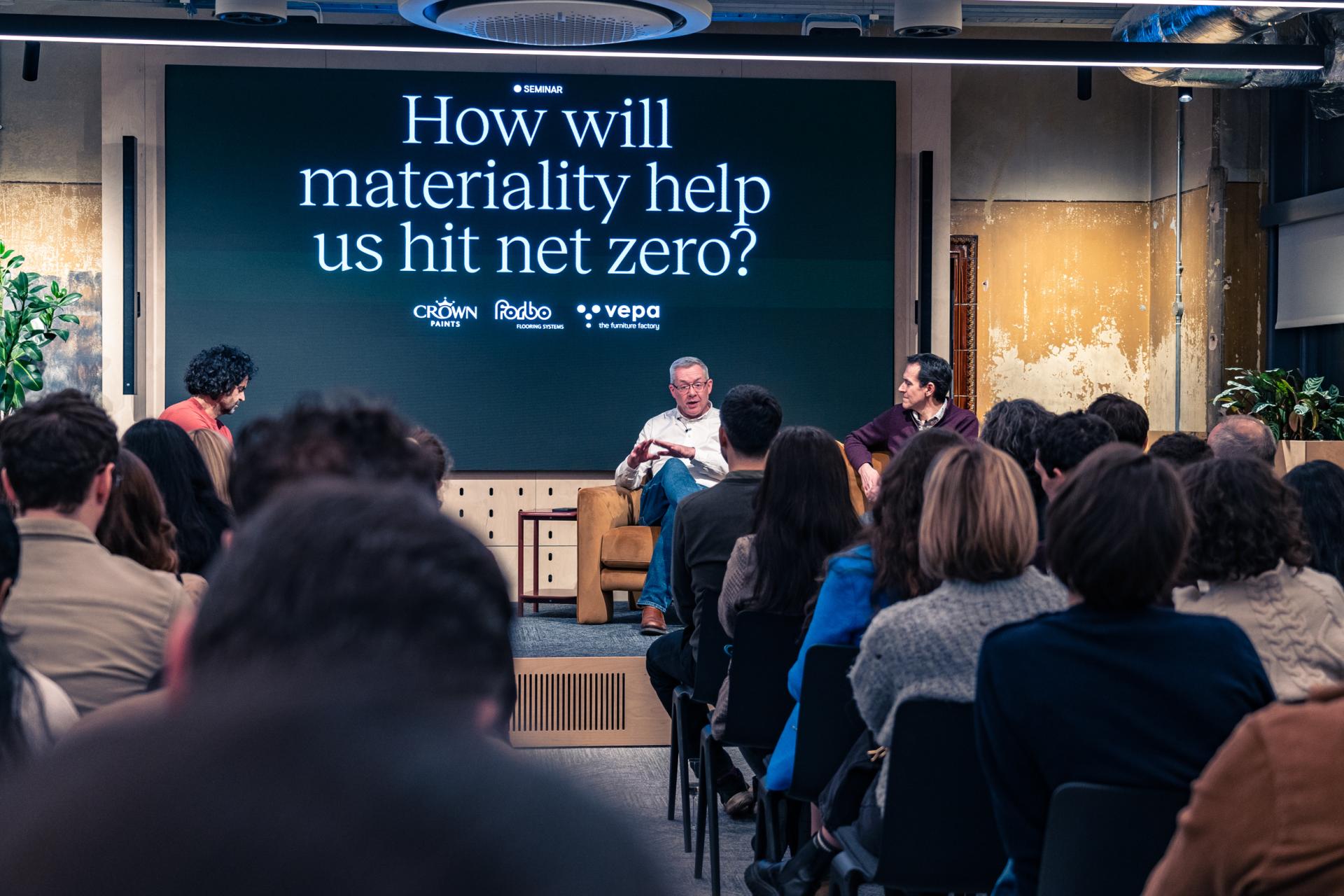

Placing this at the centre of our first seminar for 2025 at Material Source Studio Manchester, we invited two panellists with a wealth of experience in their respective fields to offer their views in answer to the question: How will materiality help us hit Net Zero? John Whittaker, engineering director at Graphene Engineering Innovation Centre at The University of Manchester, and David Leversha, director & net zero carbon lead, WSP.

In discussion with host, David Smalley, director, Material Source, the topics covered ranged from the importance of embracing innovation to support the new UK Net Zero Carbon Buildings Standard, to the challenges facing architects and designers, from cost to insurance, and potential paths forward as an industry collective.

Above all else, in what was said by our panellists and the audience during the session, an overarching message was communicated clearly. Collaboration is the only way we’ll hit Net Zero. And for the first time, the UK Net Zero Carbon Buildings Standard takes into account all the voices in the built environment sector to make this collaborative approach come to fruition. ‘Hope’ has turned to ‘action’.

Will achieving decarbonisation be easy? No. But the role of architects and designers will prove pivotal. Read on for a snapshot of the evening’s key takeaways.

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Credit: Tim Ainsworth

What is the UK Net Zero Carbon Buildings Standard?

To start, David Leversha provided an overview of the new ‘Standard’ – also referred to as NZCBS – compiled to empower built environment professionals to “pull in the same direction”, as audience member, Robert Hopkins, director & head of sustainability, AHR, nicely put it.

The result of, “a wonderful number of organisations coming together to look at the definition of decarbonisation in our buildings”, the UK Net Zero Carbon Buildings Standard, seeks to offer, “one single Standard for everyone to get behind.” The advice that was independently produced (with all best intentions) led to differing definitions and targets. So two and a half years ago, Better Buildings Partnership, BRE, The Carbon Trust, CIBSE, LETI, RIBA, RICS, IStructE and UK Green Building Council (UKGBC) came together in alignment. And NZCBS is the outcome.

“The Standard defines the decarbonisation process for a Net Zero aligned building. And this is through a bottom up assessment in terms of what’s reasonable to be delivered, and top down, asking what’s the UK carbon budget, and splitting it down into sectors and the buildings anticipated to be constructed”, David explained.

“A range of numeric targets have been set, as well as pertinent requirements such as avoiding fossil fuels.”

Though an extremely positive measure for the UK built environment sector, David alluded to the challenges existing in the relationship between the “ambitious numerical targets exceeding the current decarbonisation rate of materials such as steel and concrete.”

The question that needs to be answered then, David Leversha suggests, is: how do we achieve those targets if our core building materials don’t currently allow?

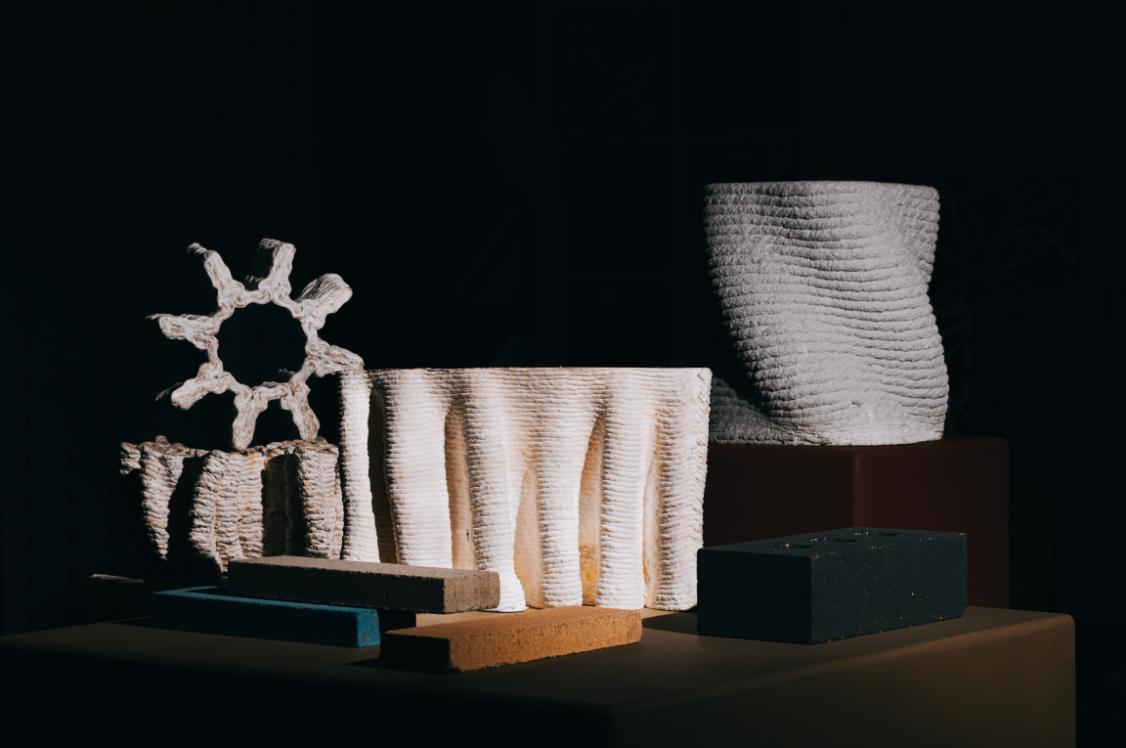

It can be addressed three-fold, he believes. Firstly, through embracing innovation. Secondly, through looking to traditional materials that may have fallen out of favour. And thirdly, through repurposing and retrofit.

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Isolation & 2D materials

One such innovation, discovered in Manchester 20-years ago, is the 2D material, graphene. Low carbon, fire retardant and strengthening, it’s considered a ‘wonder material’ with a wealth of potential.

John Whittaker explains, “If you isolate one atomic layer of carbon, you get graphene. And its bond strength is that of diamond. 1 gram of graphene covers 2,000 square metres – it has a huge surface area. When you start to engineer graphene into standard systems – such as a polymer, for example – you can increase its strength by 20-50%. Or you can remove material from the polymer, add the graphene in and remove the weight while retaining the same virgin strength.”

In built environment, this particularly applies to cement and concrete – two ‘problem areas’ associated with carbon emissions in construction.

On the face of it, graphene sounds like an obvious choice. It's now at the commercial scale in production and in some application, with numbers growing year-on-year.

At Material Source, we’ve long provided a platform to champion new material innovations, such as graphene, plus the likes of hemp and timber – both also emerging from this particular discussion as being beneficial to achieving Net Zero.

David referred to hemp as a “wonder crop” as it can be grown in the fourth crop cycle, without pesticides, and it sequesters carbon 4-5 times faster than forests. “From an ecological perspective, it’s perfect”. When paired with timber panels, David commented, it has fantastic breathability and thermal properties.

Though these solutions may work well in interior schemes, audience member Owen Tracey, senior architect, Baker Hicks, made the point that most architects are reluctant to specify anything that isn't a euroclass A rated material - "which hemp isn't, so it's unlikely we'd ever specify it for insulation, for example", he said.

Credit: Tim Ainsworth

Credit: Tim Ainsworth

What’s the real cost of sustainability?

On the theme of potential blockers such as this, host David Smalley asked the audience – via Slido – to share the challenges they face when trying to push this type of material innovation to clients.

As you’ll see from the word cloud, undoubtedly, the biggest issue they’re facing is cost. Does sustainability really cost more? And who’s most receptive to innovation? David put the questions to the panel.

Credit: Tim Ainsworth

In answer to the question on cost, David Leversha thinks not. In a recent project by WSP for Greencore Homes, David shared that an embodied carbon study carried out by his team helped the developer scale from producing 15 homes per year to receiving half a billion pounds of investment. How was this achieved? Though proving cost neutrality when compared to traditional housebuilders.

David highlighted a PWC report published this year (January 2025) which states: “Climate related investments six times more likely to have resulted in increased revenue than decreased revenue”, to bolster the point.

Moreover, research by Knight Frank indicates significant valuation uplifts for a range of BREEAM and NABERS accredited buildings, which have to be factored into project viability assessments.

He also added that the UK Green Building Council when looking at cost on a like for like basis has “found sustainable buildings to be just 0-5% more expensive”. But, when you drill down into that, David says it’s still not revealing the whole picture. “When you’re talking about a PassivHaus house, if you design it so it’s more air tight then you don’t need heating. So the whole point of looking at fabric-first for buildings is that you then don’t need as much MEP equipment, for example, saving on cost."

There is a drive for innovation, David Leversha says, and it comes from designers, investors, planning requirements (mainly in London) and clients. "Ultimately there is a real mix of drivers and we can all positively influence the outcome".

In contrast to cost being a hurdle, consultants, trying to do the “right thing”, David feels are moving the sector on. “Just as I’m sure many of you in this room are driven by a moral stance, we’ve all got a professional interest to drive this forward. In our projects, it’s working with our clients, and if we think in a brief there’s not much in there in terms of what we should be doing, but they have a national or global strategy, that’s when I’d be flagging it to the project manager.

“It might be saying risk factor number one is that there’s a national or global strategy that’s saying you should be doing X, Y, and Z – we can continue going on and ignoring that, but down the line you’ll get a tap on the shoulder”…

“So, you’re making them feel uncomfortable?” David Smalley asked.

“Absolutely”, said David Leversha. “And I think we all should be doing that. We need to be bold. We need to find the right leaders within our client teams. Ultimately, we’re saying, ‘this is going to future proof you. We can see what your company is saying, or just look at what’s happening out there in the industry.’”

“It’s also about early interventions so you start off with a really low carbon option rather than start with a high carbon option and then fight physics.”

Could this evidence then support architects and designers in convincing their clients? Should they push back when they hear the word ‘cost’? Potentially, says David, but every client has a distinct “set of levers”, and it’s about understanding which ones to push and when.

“Some clients will want to do the right thing morally, for others it’ll be a focus on cost. You have to find the right lever to drive your projects.”

More than anything, David Leversha says: “We need to articulate value. Instead of trying to design out carbon later on when it will cost more, let’s design intelligently at the start so we’re not bolting anything on at the end.”

John agreed, “You can’t just look at one component, you need to look at entire lifecycles”, he commented, in reference to a project undertaken with Ford, utilising its existing supply chains but adding extra value through the use of graphene.

In John’s experience, motivations around materials have moved on from “bigger, stronger, better”, to “cheaper, sustainable, low carbon”. And this has filtered through from the government to the public, clients and end users. As a University, Manchester has been set the challenge of supporting the meeting of Net Zero targets because of “the critical position we’re in”.

The UK is at the forefront of innovation – John Whittaker

However, he shares that it’s “highly difficult to get new materials into the construction sector – as it’s regulated and optimised.”

The benefits of doing so though, are vast. “The manufacture of cement generates 6-8% of the world’s CO2 emissions”, John commented, “So any reduction in that is significant.

“We have 10-years’ worth of data to verify that graphene can reduce the amount of cement needed – but getting through regulators is one aspect. Price was another – graphene was hideously expensive at £10k per kilo – now it’s £500 per kilo. But it’s about value.”

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Less is more

John highlighted the need for circularity and a “whole ecosystem approach”. Using an example of graphene in antifoulant paint applied to the hull of ships to deter coral in attaching itself, John shared that an energy saving of 10% could be achieved on a global scale. While this doesn’t directly impact built environment, when considering the transportation of materials for construction projects, it all feeds into the end Net Zero goal.

Reuse is a big area of opportunity, David Leversha says. And this view is shared by audience member, Jasper Sanders, founder, JS+P, “Our mission is to reuse and repurpose buildings, retaining as much existing fabric as possible in order to minimise waste and reduce embodied carbon.”

For construction, David highlighted the reuse of structural steel. On speaking to a national recycling organisation, he discovered that at any given time, they have 100,000 tonnes of structural steel going through their plants. “You can save 97% of the embodied carbon if you deconstruct, clean-up, test, and refabricate.”

The benefits not only lie in the embodied carbon, David said, but also in the pricing. “The steel was being sold at circa £250 a tonne as scrap, whereas new steel cost circa £800 - £900 a tonne, thus we have circa £600 a tonne to pay for deconstructing (rather than demolition), cleaning, testing and storing. So it’s a complete no – brainer, why haven’t we been doing it?” David asked. “Because it’s easy to spec new steel”, he added.

“There’s effort and energy needed and working with peers and collaborators. Whole cross-party support – developers, insurers, demolition contractors”, said David Leversha, “and it is hard work – but we need to change industry. We have to focus and work together.”

“Are you positive?” asked David Smalley. “I am positive we will hit Net Zero as a globe”, replied David Leversha, “but the challenge lies in at what speed we do it.

“What we should be looking at is what we can influence, and what we can control – don’t worry about what others are doing. See what you can drive through in the next 12-months to make change with your clients.”

It’s about working with clients to identify opportunities – David Leversha

A question from the audience stressed the point that, for designers, innovation is a priority, but how can they control it being value engineered out later down the supply chain?

David Leversha’s philosophy is “use less stuff” – “now, stuff could be energy, money, carbon, or materials – and if you can save on the materials, and save on energy, then you should be saving on money too.”

He again brought up the need for early engagement with partners – “make sure you have the right people involved, the right solutions, and that you’re working with nature and not against it.

“As an engineer, I love a challenge, but let’s get the basics right.”

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Be bold

Audience member, Saalim Elhaj from The University of Manchester, asked how the collaboration that David Leversha speaks of will work in practise – “As architects, how do we change the trajectory set by contractors sub contracting to get buildings up?”

“Taking ownership”, is the answer, David says. In the case of the repurposed steel, David explains it took a whole team approach, from the demolition contractor to the fabricator and end user client.

“Get the whole team onboard so they all think it’s a no-brainer. Set the scene in peoples’ heads on great solutions.”

Is this the point David and John would like to sum up on? asked David Smalley, as the discussion came to a close. “Be bold”, said David, “try not to take no for an answer, work around blockers. Collaborate.”

“And put the demand for decarbonisation through the supply chain”, said John, “because ultimately, that’s where it’ll make the most difference. Innovation will follow the demand.”

This drive for greater collaboration is happening right here on our doorstep, with audience members Alex Esfahani, senior architect, Chapman Taylor, and Jack Poulton, project architect & PassivHaus designer, SimpsonHaugh, having set up a Sustainability Steering Group, hosted out of Material Source Studio Manchester.

So if you’d like to take action and get involved in initiating change straight away, contact Alex and Jack for more information.

We were also joined by members of the Climate Action Student led Group at the Manchester School of Architecture, firmly committed to driving change in the sector.

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Credit: Tim Ainsworth

Though the seminar ended here, the conversation doesn’t, and we’ll be sharing more articles on the topic of decarbonisation in the coming weeks.

In the meantime, a huge thank you to our panellists for their insight shared, to all our guests, and to our supporters for the evening, Crown, Forbo, Vepa – all Partners at Material Source.

Our next Seminar takes place in Glasgow on 11 February 2025. Get your ticket here.